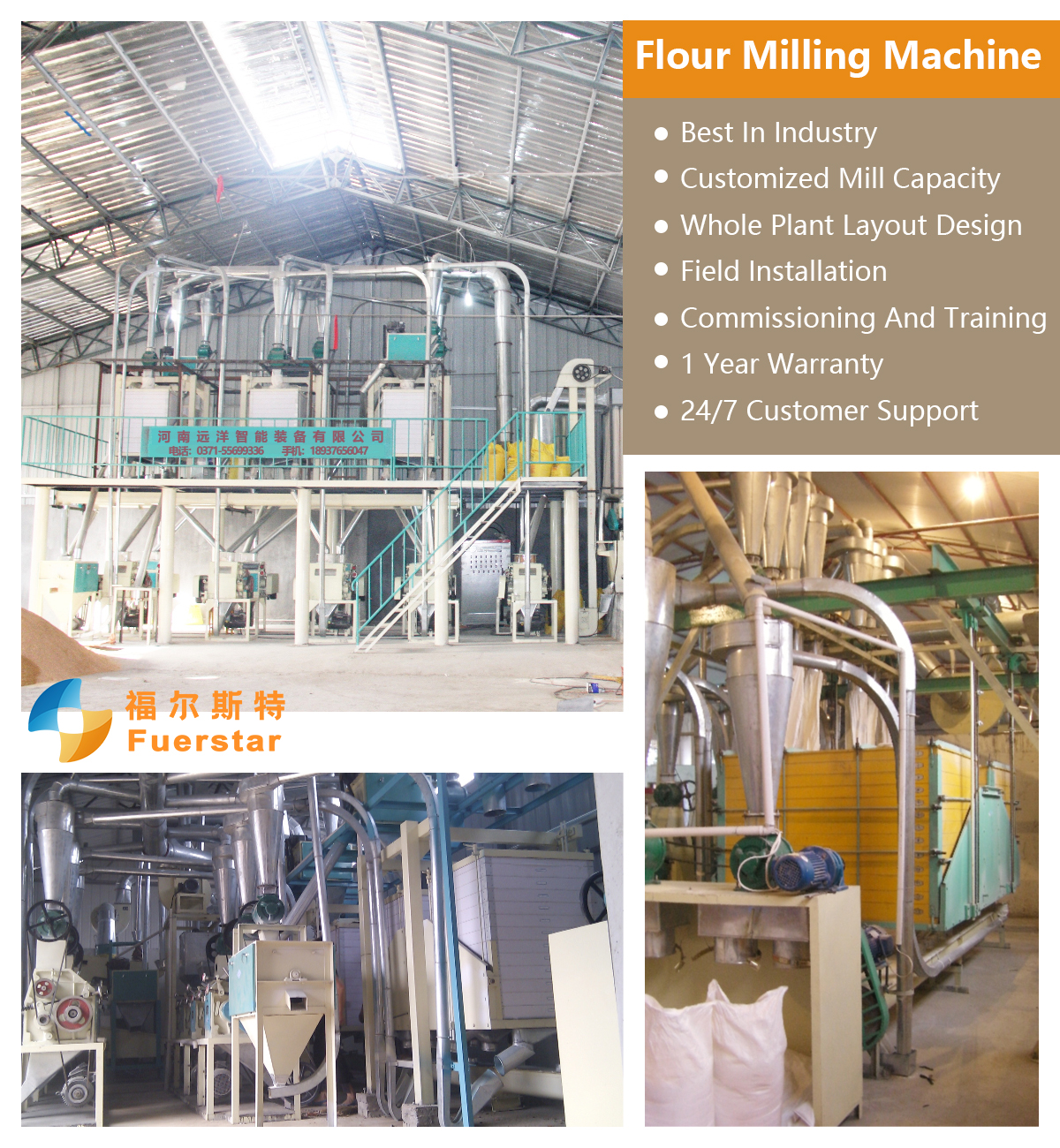

Fuerstar is a leading grain processing machinery manufacturer in China. Offer not only single flour mill machine, but also small flour mill plant (2TPD ~ 10TPD) and complete set of flour processing plant (20-1000TPD) for processing wheat, corn, cereals and so on. We have helped our customers to set up flour mill projects in many regions, like Ghana, Zambia, Argentina, Ethiopia, Uganda, etc.. Depending on the reliable quality, reasonable price and professional experiences, Fuerstar is definitely the Best choice!

Types of 50-100 TPD Wheat Flour Milling Machine

We have a daily production capacity of 20-40 tons of wheat milling plant which is constructed with steel platforms for open warehouse type buildings. Compact mills typically require two to three stories in height to provide you with an efficient wheat milling line.

- Low construction cost, small investment;

- Small land occupation and short construction time;

- Extensive use of smooth rollers ensures high quality flour;

- It is the ideal solutions for small and medium-sized flour mill to produce different grades of flour.

▼Technical Specifications

Model | Capacity(t/d) | Total Power(kW) | Building Size (m) |

FS60 | 60 | 220 | 30×8×10 |

FS80 | 80 | 330 | 30×8×12 |

FS100 | 100 | 350 | 32×10×12 |

FS120 | 120 | 450 | 36×10×12 |

FS140 | 140 | 510 | 36×10×12 |

| Final Products: Wheat Flour, Wheat Bran | |||

| Yield Rate: (1) Wheat flour 75% (2) Wheat Bran 25-30% | |||

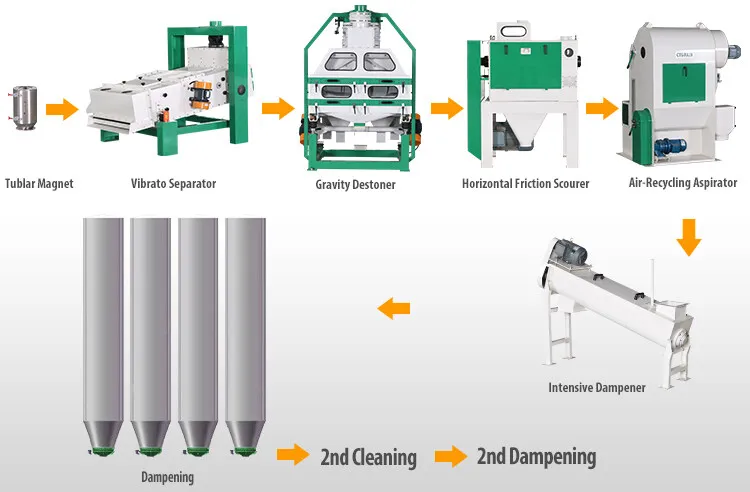

▼Overview of the Wheat Milling Plant Process

Cleaning→watering→grinding→sieving grading→powdering→packaging, etc. (The specific process needs to be customized according to the actual needs of customers)

1) Pre-cleaning:

After harvest, wheat may be mixed with straw, rope, stone, brick, dirt and other large impurities, which will damage the processing equipment or block the piping system.

Therefore, the preliminary cleaning process is required before wheat is stored.

To ensure the quality of flour and protecting the processing equipment, before entering into the milling process from temporary storage, the pre-cleaned wheat needs further cleaning. This process utilizes a variety of means, such as screening, aspiration separation, magnetic separation, stone removal, wheat scouring, optical sorting and so on.

Features:

—Combined cleaning methods to remove impurities to the maximum extent.

—Easy operation & maintenance;

—Low power consumption, well-sealed, dust free.

2) Milling:

Achieve high-quality flour through a gradual reduction of wheat kernels using advanced grinding and sifting techniques. Roller mills and sifters ensure optimal separation of bran, endosperm, and germ.

3) Packaging:

We offer various styles tailored to customer need, featuring high accuracy and full automation.

▼Why Choose Our Wheat Milling Machine?

Decades of Expertise: Our team has expertise in design, automation and equipment manufacturing.

Cutting-edge Innovation: Our flour milling machines and automated grain processing equipment deliver high precision, low loss and safe, quality output.

Resource Advantage: Leverage our decades-long experience for world-class solutions in flour processing and grain management.

Market:Our small-scale wheat milling machines cater to a diverse market, including:Local millers and entrepreneurs,Agricultural cooperatives,Food processing businesses and more.

Choose excellence, precision, and innovation for your wheat milling needs. Trust our flour milling machine production line to deliver exceptional results.